How to greatly enhanced bioavailability through particle size reduction

Case Study: Particle Size Reduction

A Particle Solutions client experienced a 40% increase in bio-availability through particle size reduction. Like most programs, the client was progressing what they hoped to be a simple immediate-release formulation. The drug load for this program was not insignificant due to compound solubility. The client decided to try particle size reduction in hopes of improving oral bioavailability. The result of the particle size reduction was a ~40% improvement in bioavailability.

Particle Size Reduction

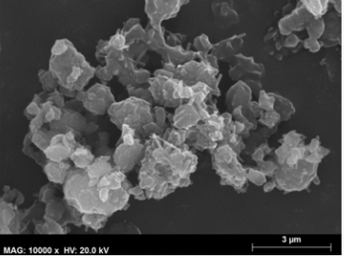

The particle size reduction method chosen for this program was jet milling. Particle size reduction by jet milling for particle size is accomplished by causing the particles of API to collide at high speed within a chamber. The collisions are driven by compressed air or nitrogen depending on the program. The particles continue to travel a circular path within the mill and remain at the outer edge of the mill until the particle experiences significant particle size reduction. The key to the process is that inertial forces dictate the particle path for larger particles thereby keeping the particle at the outer edge of the mill. As the particles collide they fracture. The new lower mass particles formed by fracturing will travel a path toward the center of the mill, carried by the exiting gas flow. Once at the center, the particles will exit to the catchment.

The key benefits of particle size reduction by jet milling are:

Energy for particle fracturing is applied via nitrogen or other gas so heat is not applied to the API.

The process is repeatable with narrow particle size distribution.

It is extremely unusual for amorphous material to be created by the process.

There are no moving metal parts or risk of metal contamination.

Formulation

The immediate-release formulation for this program was unremarkable. The formulation used standard excipients and surfactants. The unit operations were also standard, wet granulation, blending and tableting.

Why Particle Size Reduction Works

The first step in understanding why particle size matters is to explore the differences between solubility and dissolution. This is important because the gastro-intestinal tract (GI) is a dynamic system where time is a critical element. We will talk more about that later.

“Solubility is the capacity of a solute to dissolve in a pure solvent in specific environmental conditions.” “Dissolution, in simple terms is the process of a solute dispersing/dissociating in a solvent, forming a molecular level, chemically and physically homogenous dispersion, called a solution. In contrast to solubility, when we speak of dissolution, it is understood that rate is a major consideration.”

Smith, Blaine Templar. Physical Pharmacy, London, UK, Pharmaceutical Press, 2016.

Addition of solubilizing agents like surfactants can change solubility while particle size can directly impact dissolution.

The dissolution rate can be expressed via the Noyes–Whitney equation:

dm/dt = A (D/d)(CS-Cb)

dm/dt = solute dissolution rate (kg . s-1)

m = mass of dissolved material (kg)

t = time (s)

A = surface area of the solute particle (m2)

D = diffusion coefficient (m . s-1)

d = thickness of the concentration gradient (m)

CS = particle surface (saturation) concentration (kg or moles/L)

Cb = concentration in the bulk solvent/solution (kg or moles/L)

Micronization creates API of consistent particle size and therefore predictable dissolution rate. Micronization not only improves bioavailability but also improves variability of exposures.

The key take away from the Noyes-Whitney equation is that dissolution rate increases as area A increases for a quantity (mass) of drug as particle size goes down.

Particle size and the gastro-intestinal tract

It is critically important to improve dissolution rates to take advantage of in/out flows of GI fluids, transporters and passive permeability.

The goal of any solid oral dose formulation is to ensure target clinical exposures as efficiently as is practical. We use a simplified model to think about the GI tract. We think about the GI as a long straight pipe that has different characteristics by region. These characteristics include fluid amounts, surface area, pH, and permeability and transporter concentrations. In addition to these characteristics varying longitudinally, there is dynamism at each point along the way (i.e. movement along the radial direction). Fluids continue to come into and leave the GI, and transporters become more or less active as the contents of the GI move along toward the colon. Given this dynamism, time is of the essence. It is critical to improve the dissolution rate of your dosage form so as to leverage all of the GI functions that are in your favor in the proximal regions. Reduced particle size can allow a dosage form to achieve dramatically higher concentrations at similar doses.

Conclusion

Particle size reduction is an effective strategy for dramatically improving bioavailability for low solubility compounds. Jet milling is a relatively benign way of achieving particle size reduction without changing the crystal structure or creating impurities.

In this project we achieved ~40% improvement in oral bioavailability

The bioavailability increase is the result of significantly increasing dissolution rate through particle size reduction.

In addition, particle size reduction can reduce batch to batch variability by delivering consistent crystal size and therefore dissolution results.

Comments